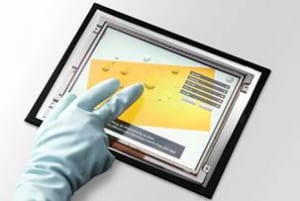

KAWASAKI, JAPAN, May29, 2015 ––– NTL Technologies, Ltd. (NLT, President: Susumu Ohi; Head office: Kawasaki, Kanagawa) has developed new prototypes which applied “Wet & Glove” technology enabling projected capacitive (PCAP) touch panels to be operated even when the screen is wet and the operator is wearing gloves.

The prototypes allow the touch screen be operated even when the operator is using a medical gel on the surface of the screen, or when the operator wearing gloves up to 5 mm thickness. With these added capabilities coupled with NLT’s advanced product specifications, this touch display is ideally suited for high-end medical, such as surgical or examination equipment used with gels or gloves up to 5 mm thickness. The touch display may also be useable in equipment in work environments where thick gloves (5 mm thickness or less) are used as protection against certain hazard.

The main features of the NLT’s Wet & Glove technology are as follows:

(1) Combination of two detection methods

Touch coordinates are detected using a combination of mutual-capacitance and self-capacitance sensors. This enables the touch position to be detected with high precision even when the screen is wet and the user is wearing gloves, and means the panel can also support multi-touch functionality and gesture operation.

(2) Proprietary sensitivity adjustment tool enables operation while wearing thick gloves

Due to the touch panel’s sensitivity adjustment, using a proprietary touch panel controller developed by NLT, accurate position or touch detection is still possible even when the screen is wet and the user is wearing gloves.

(3) Wide variety of design specifications accommodated

Wet and Glove touch technology also supports various design options such as glass bonding or surface film, as with all PCAP products NLT offers. Treatments to protect against fingerprints or reduce glare can be accommodated so end-product designers can set specifications to suit a broad range of applications.

PCAP touch panels are now being adopted in a rapidly expanding range of industrial equipment for their superior features such as multi-touch functionality and gesture operation. This trend is particularly marked in devices for use in special environments – such as outdoor equipment or medical equipment, for example – where the touch panel could easily get wet or have medicines and other liquids spilled on it, and might need to be operated by someone wearing gloves. However, these conditions would pose a problem for the position detection method used in conventional PCAP touch panels, which cannot function properly when used by a gloved user while the screen is wet.

Although two position detection methods – self-capacitance and mutual-capacitance – are available for use in PCAP touch panels, the one typically used in conventional models is the mutual-capacitance method, which supports multi-touch functionality. However, with this method the detection capacitance changes when drops of water come in contact with the screen, so position detection becomes less precise when the screen is wet, and furthermore, when the operator is wearing thick gloves, detection sensitivity decreases. By contrast, the self-capacitance method is not affected by the change in capacitance caused by water drops, so high precision detection is still possible when the screen is wet; however, supporting multi-touch functionality presents a problem.

Through on-going development of their PCAP technology, NLT expects to begin mass production of PCAP model products adopted this Wet & Glove technology in the near future.

The prototypes of the LCD modules that applied Wet & Glove technology are showcased at Display Week 2015 (#719), June 2-4 in San Jose, California, USA.